New Photos Reveal Tesla Model 3’s Aluminum, Ultra High-Strength Steel Blend

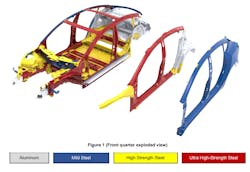

Aug. 24, 2017—New photos from Tesla Model 3’s Body Repair Tech Note posted by Teslarati reveal a metal composition for the vehicle’s structure, utilizing a combination of aluminum and ultra high-strength steel.

Photos, posted to Twitter and shared on Reddit, illustrate just how Tesla has been able to achieve a Model 3 body structure design. Tesla uses three different grades of steel, from mild steel used on the outer body structure where it’s designed to absorb initial impacts, and high-strength, to ultra high-strength used in the vehicle’s core. For instance, the A-pillar and B-pillar is fabricated from ultra high-strength steel in order to provide maximum rollover protection. The Model 3’s front frame rail is a composition between high-strength and ultra high-strength steel, and serves as the main support for the front “crumple zone.”

Tesla Model 3’s body repair manual notes that “Structural Pulling” is not allowed, meaning that any structural component that’s welded, weld-bonded, riveted, or rivet-bonded to the vehicle can not undergo a process wherein the straightening of structural parts are facilitated through a hydraulic pulling machine. Doing so would compromise the yield strength of the metals being used.

Also noted in the Model 3 structural diagram is the “underbelly” that serves as the main support for Model 3’s skateboard style battery pack, similar to what’s used in its older Model S and Model X siblings. The entire underside of the vehicle is fabricated from high-strength steel.

Side impact safety on the Model 3 is bolstered by a fully fortified closed steel structure in ultra high-strength steel.

Lastly, lightweight aluminum is introduced in areas of the body structure that are less susceptible to accidental impact such as the trunk floor and wheel wells. Using aluminum helps Model 3 maintain a relatively light curb weight of 3,549 pounds. for the standard version and 3,814 lbs. for the Long Range Model 3 with larger (and heavier) battery pack.