They go way back; way, way back—58 years, to be exact.

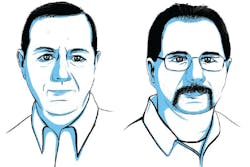

Even crazier? During the six decades Randy and Bob Miller have been brothers, they’ve spent 40 of those years together at their shop, Randy and Bob’s CARSTAR in Chicora, Pa.

“We’re not quite sick of each other yet,” Randy jokes.

The brothers bought their first car together at the ages of 12 and 13 (Randy has one year on Bob)—a ’53 Chevy with some serious body damage. They fixed it up and sold it for a profit, and then, six years later, they took over the family auto repair business.

Since then, Randy and Bob’s shop has become an integral part of the community.

“Randy and Bob’s CARSTAR has … always been a big part of their local community, and regularly participates in charity events,” wrote CARSTAR marketing manager Bradley Gillie in his FenderBender Award nomination of the brothers. “The shop has virtually been in the same spot for decades, and has had a loyal customer base that spans generations; just like the Miller family itself has had multiple generations working there.”

With 84 percent of their business coming from repeat customers, Randy and Bob firmly believe their success can be attributed to a healthy working environment. The brothers share the philosophy on employee-management relations they’ve cultivated:

They’re not just employees—they’re business partners.

Randy and Bob understand that their employees will be more motivated if they feel they’ve provided input on how to grow the shop.

“We get our employees to buy in with us,” Randy says. “They’re more like business partners. We’re all here together working for a common goal. That’s a key thing.”

This means involving staff in company decisions, from new equipment purchases to the shop layout to improving cycle time.

When the shop built a new facility in 1997, it first consulted a contractor and architect for design ideas.

“And then we asked technicians on the body and paint side,” Randy says. “That was invaluable input in how our total building was designed for flow and efficiency and ease.”

Share key numbers with employees.

The Millers engage with their employees on a daily basis, sharing key performance indicators, such as car count, cycle time and CSI scores.

“Everybody shares a lot of the company numbers so everybody knows where we are each day, where we need to go,” Randy says. “We’ve used that for so long that it’s not a hard practice to do. If we’re running behind, everybody knows to pick up the pace. If we’re ahead, that’s great, let’s keep that pace up and not slack off. As a group, we’re looking for ways for them to do better.”

Create an open-door policy.

Having grown up in the shop, Randy and Bob understand what it was like to work their way up the company ladder. That’s why they try to eliminate that hierarchy in their shop. They feel employees and management should have a collaborative relationship.

“I try and work with the employees on a daily basis,” Bob says. “I am an estimator here, which requires me to be on the floor quite a bit and I have a lot of interaction with them on a daily basis, and I believe that helps a lot when there are no boundaries there.”

“One of the things that I really find helpful is they have an open-door policy, so if I need assistance or help or have a question, I know I can walk into Randy or Bob’s office at any time and they’ll give me time,” says marketing manager Natalie Butcherine. “They always make time for the employees, no matter how little or big your questions, issue or concern is.”

Hire employees who care.

Randy says the shop’s culture is a shock for many employees, so finding the right fit is crucial to keeping that culture intact.

“We’re very systematic, and that’s probably the first shock they have, coming into somewhere where it’s totally organized, where there’s a system for everything. We don’t like disarray,” Randy says. “We find that some technicians can’t survive in new systems, because maybe they’re the ones that cause disarray. But the people we have here now when they arrived absolutely love it because it’s profitable for them and it’s profitable for everyone.”