FB Exclusive: Independent Shop Owners Develop Robotic Paint Drying Equipment

May 18, 2017—Two American independent collision repair shop owners are mere weeks away from finshing developing their own robotic paint drying equipment.

Tim Beal, owner of Beal’s Auto Body & Paint in Prescott, Ariz., and Byron Davis, owner of Auto Body Specialties in Springfield, Ore. (both of whom have been featured in FenderBender), started their company U.S. Auto Cure and have partnered with mechanical and electrical engineers that have worked in the computer and aerospace industries to develop the Phoenix1000 curing system.

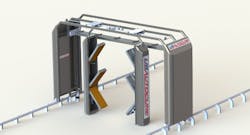

Most robotic paint drying equipment—which drastically improved cycle times for European shops years before the technology came to the U.S.—comes with a complete robotic arch mounted to a track on the ceiling of a paint booth, which passses over a vehicle at roughly three feet per second; a half-arch model, designed primarily for prep bays, that also travels on a mounted ceiling track and can be maneuvered to directly hit specific areas of vehicles; and a handheld version for smaller jobs.

David Aldrich, an electrical engineer, took Beal and Davis’ combined personal experience with infrared paint curing systems (which have been featured in FenderBender heavily in the past) and applied it to the design of the Phoenix1000 with his fellow engineers, who studied the several other options on the market to form their near-ready product.

Beal says that’s largely due to the costliness of the systems (one can expect to spend, at the very least, $50,000 to $100,000, says Steve Trapp, North American services manager for Axalta Coating Systems) and the lack of American-based service centers whenever the equipment malfunctions.

While Beal's Auto Body experienced vastly improved cycle times and had its best sales month ever upon implementing robotic paint drying equipment, Beal says mechanical issues, space restraints and service frustrations kept his shop from reaching its full potential, and oftentimes impeded production.

Thus, his partnership with area engineers began 13 months ago. Within 4-6 weeks, Beal says the equipment will be finished and ready to market. He says the system will be “completely modular” (meaning it can adapt to a vehicle of any size) and operable with a smartphone or tablet.

FenderBender will follow up in the next couple months with more information once the Phoenix1000 is complete.