Organizing Vehicles for Efficiency

Visual tools are important for streamlining processes and eliminating bottlenecks, and your shop’s parking lot is one of the most important visual tools, says Dave Dewalt, manager of business consulting services at Sherwin-Williams. Dewalt says implementing a vehicle organization system can streamline the repair process and increase communication between departments in the shop. He discusses how to organize vehicles in your shop and maximize the use of your parking lot.

Start with the main departments you have designated in your shops. Now, take a look at your average daily workload that comes in and leaves, as well as how many cars you typically have as work in progress. That will give you an idea of how many parking spots each department will need.

Utilize as many visual tools as possible throughout this process. For example, I am a big fan of the magnetic hats in a variety of colors. Create a chart that dictates what each color means, such as an orange hat for framework needed, red for awaiting parts, blue for ready for refinish. I also use a labeled sign to dictate where the sections are.

I also use tracker boards to further emphasize the visual control. The front office has an information board that displays pertinent information about each job. Each department then has its own board, which looks like a keyboard. As the vehicle is moved, the keys go to the designated keyboard in the next department. See Dave’s system below.

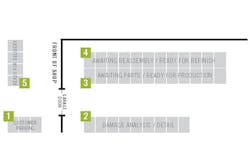

Parked Vehicle Movement Guide

Dave Dewalt’s 5 step system for organizing a parking lot to achieve a streamlined repair process.

1. Customer Parking Area

Start with the designated area where customers pull into. The CSR immediately comes out and does a formal check-in, then alerts the production manager via walkie talkie that a new vehicle is ready for damage analysis.

2. Damage Analysis

The production manager would then park it in the five spaces designated for damage analysis, which is in addition to the two spots they have in the building for in-process vehicles.

3. Awaiting Parts/Ready for Production

After damage analysis, they would park it in one of the 12 designated spots for awaiting parts/ready for production. If a vehicle is awaiting parts, a red magnetic hat is put on top of the car. Once it is ready for production, the red hat is taken off and replaced with a green magnetic hat.

4. Awaiting Reassembly/Ready for Refinish

When the bodyman is done with production, he would move it to the awaiting reassembly/ready for refinish designated spots. Again, I would attach a blue magnetic hat when it is ready for refinish and replace that with a white magnetic hat when it is awaiting reassembly.

5. Ready for Delivery

Cars ready for delivery after detail are parked in designated spots out front. The CSRs then know that the quality control process has happened and the car is ready for the customer to pick up.

One final designation is employee parking. It is important that they have specific spots, too, so that their vehicles do not interfere with the flow of the customer vehicles.