As the onetime owner/operator of Baltimore’s Auto Glo Body Shop, Bernie Blickenstaff built the business into a million-dollar company in seven years, then opened Superior Auto Paints, which grew into an eight-store company serving scores of collision repair shops in the Maryland/Washington D.C./Virginia area. Blickenstaff’s success eventually led him into shop consulting and autobody management sessions, including his Automotive Management Institute course, “Motivating Employees with Productive Pay Plans,” which has been offered since 1999. Below, Blickenstaff outlines his most important, most shop-practical insights on pay plan management—in his own words.

First The Basics: What Makes Employees Tick?

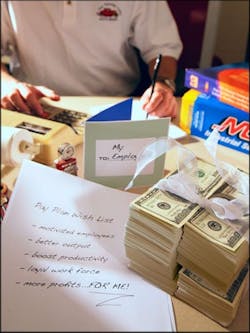

It’s a fundamental business concept: Your sales have to grow every year because your costs grow every year. So how do you grow sales? You can hire more technicians to do more work, or you can motivate the technicians you have for greater productivity and output. Although monetary compensation, itself, is not the only motivator, and, in fact, it ranks fifth on the list of the most impactful job incentives, the pay plan you create for your employees can provide a strong incentive for individual productivity while assisting you in attaining your business objectives as a company.

But because they are critical to retaining good employees—and all five top incentives are really about leadership skills and identifying what is important to your employees—I will quickly review the first four incentives, then we will focus on number five: the dollars.

The top five motivators are:

Interesting work. People want to be challenged. They want to enjoy coming to work and doing the work they are there for.

Involvement. It is important for people to feel that they are in on things, that they are involved, that they are in the know. They want to feel that they are a part of the business and that their work contributes to the shop’s success. It is important for employees to feel vested in their work.

Appreciation. Be all over your employees with thanks—for a productivity increase, for customer satisfaction, for skills growth and achievement. It is just like giving a biscuit to a dog and seeing the tail wag in response. Receiving positive reinforcement for a job well done makes people want to do—and receive—more.

Job security. If the first three things are met, insecurities about job security are overcome. This is because having the first three makes the employee feel that he or she is not only in the know, but in control of his or her own destiny.

Pay. Income is often a key factor in a person’s decision to join a company, but to some degree, everyone has a threshold, a range of financial need; and money only motivates to that threshold. Very rarely will the technicians’ financial needs meet the shop’s market-share productivity needs. For this reason, pay incentives should provide a challenge, to be understood as the business contribution that they are and provide positive reinforcement for the individual’s productivity and skill level—all while meeting or enhancing the company’s profitability goals.

What's All This About ‘What-Iffing’?

The first step in creating a motivating, company-beneficial pay plan is realizing that it is just that—a plan. There is no single plan that fits every shop; no cookie-cutter solution. Rather, each plan will have variation and be unique to the collision center; and to get there, somebody has to pencil-push it; somebody has to what-if it.

In addition, you need to realize that it is a process. You might set up all the aspects of the plan, but you can’t necessarily change everything in a day. It may take a year or more to get the plan fully implemented. Think of the plan as a concept, a vision.

To create the plan, then, you need to set strategic objectives that align with your company objectives, based on three primary factors: profitability, productivity and personnel development.

Profitability is always number one and needs to consider true compensation—that is, both wages and benefits. ‘What if’ the plan by starting with your gross profit objective then backing into the pay plan objective. What-iffing a plan means literally laying out an option then, taking it through a series of what-if queries: “What if sales drop?” “What if sales increase?” “What if productivity declines?” Then the plan needs to be balanced against all possibilities and downsides and hurdles considered. It’s not an easy task, but it needs to be done to ensure the company is prepared for and the plan will stand up against any inevitability.

Benefits, including statutory and all market-driven benefits, should be calculated as a percentage of base wages and should generally fall into the mid- to upper-20 percentile. They should never be more than 30 percent, or you will be compromising company profitability.

Productivity objectives can be met through the setting of goals for your technicians that fulfill your profitability goals and are based on the technicians’ own skills and areas of responsibility. For example, if you pay based on flat rate and you’ve what-iffed your output need to be a total of 240 hours from three technicians, you now need to set individual goals for your technicians to achieve this.

This does not mean that you simply set 80 hours as a goal for each person; rather, determine what each is currently averaging, then set a challenge to take it higher. For example, if one technician is already doing 93 hours, you may want to set a 5 percent increase as a goal; for the technician averaging 65 hours, however, you may want to challenge him to a 15 percent increase—then base pay increases on achievement of the goal.

Smart Incentives, Dumb Incentives

I’m a firm believer in incentivized pay plans, but specific incentives have to be tied to the employee’s specific responsibilities. For example, a parts manager has no control over total sales, so incentivizing him on total sales does no good. On the other hand, rewarding an applicable incentive for every employee—including your clerical staff, receptionist and car porter—can greatly enhance their job satisfaction and your own bottom line.

Personnel development can be particularly valuable for retaining and motivating long-term employees. While much of the industry pays on flat rate, incorporating a version of that based on skill level can reward employee skill-growth achievement and increase your company’s profitability.

Straight flat rate means that a technician new to the industry will make the same dollar per labor hour produced as a highly skilled veteran and will often be expected to do all the same jobs. Although there is incentive to finish more jobs to increase one’s pay, there is no motivation for skill growth. On the other hand, if you create skill levels based on specific criteria, then assign jobs and pay by skill level, you will lower your effective labor cost (ELC) and motivate technicians to increase their skill level.

Using this concept, I created four skills levels: apprentice, journeyman, senior technician and master technician—where apprentice technicians begin with light work and lower flat rates and master technicians take care of the “train wrecks” with higher rate pay. In the end, depending on the mix of technicians, my ELC can be lower even though I am paying my master technicians above standard rate. It is important to maintain a mix of skills as well. You don’t want all highly skilled technicians, or you are back to square one. Rather, you want your mix of skills to meet your workload level, then match the skill to the task.

In an industry in which it is becoming harder and harder to find skilled technicians, this enables you to take the ball into your own hands by hiring entry-level people—who are much easier to come by—and growing them internally.

The other advantage of this system is that you can team your people so the lesser-skilled technician works with one of a higher level. Not only does this enable each to take on the tasks of his/her level, it enables a cascading of knowledge and internal growth among your technicians. In addition, such a plan enhances the longevity of your older technicians, who can have apprentices working with them to do the unskilled labor. And, by fitting more technicians per stall, you reduce your stall-to-technician ratio, which increases output.

In short, pay as a motivator is limited by a person’s monetary needs. But when pay is integrated with other factors, and the incentive is within the worker’s range of responsibilities and abilities, a strategic, well-what-iffed pay plan can be the factor that drives your company growth year after year.

One Shop’s Pay-plan Turning Point

Solving the market-compensation equation in Seattle

With 11 shops, more than 190 employees and annual sales of $18 to 20 million, Seattle’s Precision Collision Inc. was at a pay-plan crossroads.

The city’s ultra-low unemployment rate and high standard of living not only meant a small available talent pool for new technicians, it also meant fast-rising salaries for those who had already earned their stripes. “If people knew what some of the techs make in our city, a lot more parents would be telling their kids to go to school for autobody repair,” chuckles Precision Collision’s Chief Operating Officer, Terry Asher-Simon.

“So we wanted to look at pay plans that would allow our existing techs at the high end to make what they need to make in the current market, while also bringing in the best new people at the lower level to assure our future.”

Front-office salary pressures also were part of the equation, as was the need to have the strongest overall financial picture possible, since much of Precision Collision’s rapid growth has been tied to its ability to purchase the property for its new locations.

“That meant we also wanted to look at how to make our pay plan work best, not only for our employees, but for us as a company,”

Asher-Simon notes. “We were very interested in linking productivity to it, for example, even though we already had some—quote—negotiable bonus incentives and so forth. And, on top of that, we also wanted to tie it all in to what all the things the insurance companies want. As you might imagine, it all started getting really complex.”

About four months into its pay-plan development process—guided by advice from BASF and Bernie Blickenstaff, as well as input from local tech schools and an internal company business-development team—Precision Collision’s updated compensation program is still a work in progress. A finished product is not expected to be ready until February or March 2008.

Still, says Asher-Simon, the company is more than satisfied that the new pay plan’s fundamentals are on the right track. “It really helped to have somebody like Bernie actually come into the shop because everything we needed to be aware of is changing so much that it can be hard to keep up with everything sometimes,” she says. “One of the things he told us was that before we made the jump, to do as much research and have as many potential models ready as we could. … A lot of reorganization is going on already.

The company has zeroed in on how to measure techs’ productivity for incentives, for example—through key performance indicators preferred by the insurance industry such as cycle times, percentage of parts, on-time delivery and Customer Satisfaction Indices (CSI)—with a few company-specific wrinkles.

“CSI doesn’t measure everything we want to measure,” Asher-Simon notes, for example. “What I mean by that is that an employee might be a great salesman but insurance companies hate working with him because of his numbers, and that’s not great. At the same time, insurance people might be very happy with another person’s numbers, but their CSI isn’t very good, which isn’t great either.”

One of the emerging plan’s strengths, of course, is that Precision Collision’s employees have been in on development meetings all along, Asher-Simon notes. “And they’re all looking forward to having a new pay plan in place. The whole approach we’ve taken boils down to really knowing our environment and adjusting to it in the best way we can."

But would the process work as well for a smaller autobody shop? “Absolutely,” Asher-Simon says. “The specific circumstances might be different, but the fundamental principles are the same.” —Chuck Nowlen