OK, my friends, let’s start with a term that’s become somewhat of a dirty word for our industry—or, really, three dirty words. Electronic parts procurement.

Be honest, just reading that last line elicited a quick reaction from you, right? It’s OK, you’re far from alone on that. In today’s industry, there are few topics that are as divisive as electronic parts procurement. There are myriad reasons, including an oft-discussed one about a certain program being mandated by a certain insurance carrier. But many of the reasons that bring about controversy with this topic are from past events, and that’s where we should leave them—in the past.

WANT TO MEET

MIKE ANDERSON?

He’s the keynote at the FenderBender Management Conference Sept. 19–21 in Chicago and will be available for questions and discussion.

What I’d prefer to do is discuss how we shape the future of electronic parts procurement, how we can make this technology a true source of advancement for the industry, how these programs can be shaped and transformed in ways that will benefit all parties involved.

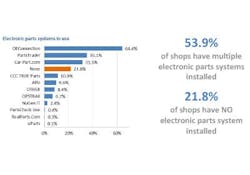

First, I want you to know a few numbers. In my company’s Who Pays for What? Survey for the first quarter of 2016, we had a couple tacked-on questions at the end about electronic parts procurement; namely, it looked at what it is that shops use, why they use them, and what their preferred systems were. It’s that last question that wound up providing the most surprising results. The system that came in at No. 1 was OEConnection’s CollisionLink, which had 43.9 percent. But at No. 2 was “none of the systems currently available” with 31.2 percent. Let’s restate that: More than 30 percent of survey respondents don’t prefer any of the systems.

This is a huge problem, and an alarm went off in my head seeing those results. So, what I did was, I reached out to some of those folks who took the survey, and asked, ‘Why is it that you don’t like any current electronic parts solutions?’ To a person, they all had almost identical answers: There are four critical things a parts solution must do, and not one of the current programs do all four of them.

There are reasons: One is that each procurement solution provider has to deal with the proprietary nature of the systems they interface with as well as the OEM data. Another is that we haven’t created a strong enough dialogue between all parties involved to create a solution that benefits everyone, including the OEMs.

In general, parts are 36–40 percent of your business, right? Well, that’s a pretty darn big chunk, my friends. Those margins will make or break your business. We must create a dialogue, reach out to your system providers. We need to have a hand in the future of these solutions. We need them to actually be solutions. Electronic parts procurement isn’t a dirty term; silence is.

About the Author

Mike Anderson

Mike Anderson, the former owner of Wagonwork Collision Centers in Alexandria, Va., operates CollisionAdvice.com, a training and consulting firm that assists shop operators nationwide. He is also a facilitator for Axalta Coating Systems’ 20 Groups in the U.S. and Canada, and is an Accredited Automotive Manager. Reach Anderson at [email protected].