Revv Report Finds Only 21% of Shops Have Optimized Calibration Processes

Key Highlights

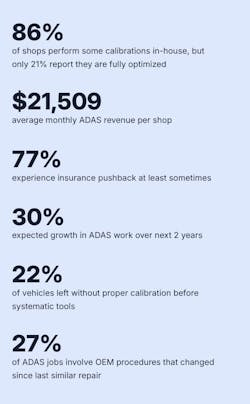

- 86% of collision repair shops perform ADAS calibrations in-house, but only 21% have fully optimized processes.

- High equipment costs ($55,494 upfront) and ongoing expenses ($18,773 annually) pose significant barriers, though many shops are satisfied with their investments.

- Training remains the biggest challenge, with nearly half of shops citing costs and time as barriers to keeping technicians up-to-date with evolving OEM procedures.

- Insurance reimbursement processes are increasingly complex, with 77% of shops receiving pushback and providing additional documentation upon insurer's requests.

ADAS calibrations continue to grow as 86% of collision repair shops perform at least some calibration in-house. However, Revv’s The State of ADAS Calibration: Industry Benchmark Report 2025 revealed only 21% of shops have a fully optimized calibration process.

The report highlights the challenges shops are facing at the rapid rate new vehicles are adopting ADAS technology but also presents financial opportunities. Out of 300 shops surveyed, the average shop generates $21,509 per month in ADAS revenue with a 9% net profit margin. The shops expect ADAS work to increase by 30% over the next two years, which should drive the revenue numbers higher.

Revv identified five key takeaways that shops are grappling with as they try to keep up with ADAS’ rapid growth.

Equipment Costs Create High Barriers

Properly equipping technicians with the tools and skills they need for calibrations is costly. Shops report an average initial equipment investment of $55,494, with ongoing equipment and tooling costs averaging $18,773 annually.

While the upfront costs are high and typically require more than a year to recoup the investment, 58% of shops report being extremely or very satisfied with their ADAS calibration equipment investment. Only 8% are not satisfied and 57% feel they got their money’s worth.

Training Is the Biggest Barrier to Growth

ADAS technology creates a difficult training environment, and 49% of shops cited training costs and time away from production as their biggest concern. An average of 27% of ADAS jobs involve OEM procedures that have changed since the last similar repair, meaning training becomes outdated quickly.

The high upfront and ongoing equipment costs are creating a two-tier market where well-capitalized shops can afford comprehensive coverage while smaller shops remain stuck outsourcing. However, even shops that have made substantial investments are turning away work due to coverage gaps, suggesting that smart equipment strategies — such as focusing on high-volume makes and models first — may be more important than trying to cover everything immediately.

Technology Friction Slows Optimization

Even shops with the right equipment and trained technicians are losing efficiency to technology friction. The ADAS ecosystem is fragmented across multiple platforms, creating daily operational challenges that slow down calibration work and erode profitability.

ADAS calibration software helps solve the issue for shops as it can identify the specific calibrations required based on the vehicle’s VIN and the repair performed, provide access to current OEM procedures that change frequently across manufacturers, and generate the documentation needed to prove compliance for insurance reimbursement.

ADAS Maturity Is Increasing Documentation Burden

Insurance reimbursement represents a critical revenue source for ADAS calibration services. As ADAS has become more normalized in the industry, insurance expectations have similarly evolved. 77% of respondents reported having to provide additional information upon insurer’s requests. Nineteen percent of survey respondents listed insurance reimbursement processes as a leading operational challenge, while 15% said insurance documentation requirements were a leading obstacle.

Since one-third of shops’ job share revenue come from insurance pay jobs , on average, the uncertainty of around payment and reimbursement creates uncertainty for shops around whether the additional equipment and training is worth the investment.

Process Gaps Create Hidden Costs

Most shops have invested in ADAS capabilities: they’ve bought equipment, trained technicians, and started performing calibrations in-house. But having the pieces in place doesn’t mean the process is optimized. The data reveals a striking gap between perception and reality. Only 21% actually report having achieved full ADAS optimization, despite 78% of shops having a dedicated space for ADAS calibrations.

Revv identified several areas where ADAS can add hidden costs to shops. Performing proper, optimized ADAS calibrations can avoid these costs and improve business:

- Time and Capacity: ADAS calibrations increase the repair time for a vehicle, but they can also be completed relatively quickly with the right technology and skilled technicians.

- Liability of Missed Calibrations: If a vehicle leaves a shop without proper ADAS calibration and is involved in another accident where the systems should have prevented or mitigated the collision, the shop could face legal liability for failing to properly restore safety features

- Reputation and Trust: Customers who experience malfunctioning systems after a repair are unlikely to return to that shop and can quickly spread bad reviews online.

- Financial Cost of a Poor Repair: When a missed calibration is discovered — whether by the customer or during a post-repair review — shops must perform the work over again, typically at no additional charge. Reworks eliminate any profit from the original repair and often push the shop into a net loss on the job.

Revv’s report concludes with recommendations for how to tackle some of the biggest concerns shops face with ADAS calibrations:

- Rising costs: Build depth in high-volume makes before adding breadth. The 43% of shops turning away work often bought too broadly too soon.

- Changing standards: Invest in software that updates automatically rather than manual tracking. The cost of missing a procedure change far exceeds software costs.

- Complexity: Consider the sublet hub model; 61% of shops receive sublet work, allowing them to specialize rather than cover everything.

- Tech shortages: Cross-train two to three technicians on common calibrations to prevent bottlenecks when someone is out.

- Liability concerns: Implement systematic identification and documentation tools like Revv. Before these, 22% of vehicles requiring calibration left without it. Finally, systemize your processes to ensure nothing slips between the cracks.

Read the full report here.