Paint supplier talks ADAS and the road ahead for body shops

Autonomous driving technology and collision repair centers face a winding road ahead, as more cars with advanced driver assistance systems (ADAS) crowd the streets. Today, many ADAS-enabled vehicles fitted with sensors and cameras can adapt their speed based on surroundings, apply the braking systems to maintain a safe distance from other cars, maintain their driving lane and park themselves. Drivers can even remove their hands and feet from the steering wheel and pedals for periods of time.

Yet, questions linger for body shop technicians on how to handle the now complex repairs of ADAS-equipped vehicles following even a low-speed collision.

Where's the ADAS?

ADAS can include forward collision, automatic emergency braking, lane departure warning and adaptive cruise control, which the Society of Automotive Engineers classifies as Level 1 and 2 on the scale of autonomous vehicles.

Automakers have installed these driver safety technologies in peripheral, easy-to-damage areas such as windshields and bumpers. These areas can house sensors that are used to reflect high-frequency sound waves to detect people, cars and other objects close to the vehicle.

These systems can be hard to detect by the naked eye. Thus, body shops rely on customer discussions, visual indicators (such as forward-facing, side view and rear cameras, and sensors located in bumpers, grilles, fenders, quarter panels and taillamps) and automakers build data to pinpoint the ADAS. The automakers' build data can provide window sticker-level information on any particular vehicle identification number (VIN), providing a comprehensive view of all vehicle descriptors. Vehicle descriptors can include a car's year, make, model, trim, color, interior, standard equipment, packages and options.

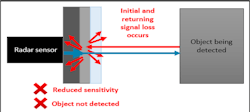

Once body shop technicians know what they face, they will have to carefully consider the repair process even after a minor collision because damaged safety components can cause serious issues for drivers. For instance, today's plastic bumpers house a host of sensors, including radar, a detection system that uses radio waves to determine objects' distance range, angle or velocity. In the past, body shops simply fixed minor bumper damage by filling scratches and then spot-painting. Today, however, body filler compounds and new paint could impair vehicle sensors.

So, with 85 percent of new cars forecast to have radar by 2025, how can body shops prepare for the next generation of vehicles?

The art of calibration and estimation

Trained technicians will have to recalibrate the sensors using specific equipment and software for diagnostics, service, replacements and repairs to meet automakers' specifications. While most dealership body shops will have the equipment, most independent collision centers do not. As a result, independent body shops will need to invest in ADAS calibration equipment to repair vehicles properly. However, according to a 2021 industry survey, only 22 percent of responding independent shops said they are equipped to perform ADAS calibrations. Thus, it could be some time before most shops are equipped to carry out in-house calibrations.

Body shops will also have to consider investing in more sophisticated estimation tools to assess the job costs of damage to driver safety technology installed discreetly in areas such as bumpers. Using historical data, predictive analytics and VIN integration, the estimation software can build a more accurate estimate for collision repair professionals.

The metallic finish issue

In addition to considering the ADAS-equipped car's technical safety and functionality components that did not exist a decade ago in its repair process, technicians will need to be aware of how certain colors and finishes can impact the sensors of these safety components.

Until recently, automakers initially opted to replace instead of repair the damaged bumper, which proved expensive and with significant pushback from car insurance companies. Automakers turned to paint and coatings suppliers to identify a better solution. PPG, for instance, partnered with many automakers to calculate the impact of all their dozens of colors, including metallic finishes, on repainted bumpers to better understand the transmission loss of radar signals.

Data showed that while the vast majority of colors do not impact the functionality of ADAS, a handful of metallic finishes did pose an issue. Thus, paint and coatings suppliers provided a more cost-effective and environmentally responsible solution (a far cry from replacing and repainting the entire bumper) to ensure ADAS functionality, driver safety and industry integrity.

Coat and painting suppliers have evaluated swapping the aluminum pigments in the metallic finish with alternatives to improve radar transmission. These reformulated colors maintain a good match to the vehicle's original finish while reducing the radar transmission loss so that safety systems can function as they should.

The road ahead

While automakers typically plan five years out when choosing color styles to stay ahead of mobility trends, a greater partnership between paint suppliers, automakers and body shops seems to be emerging. That partnership will prove key to developing the next-generation technologies that retain radar capability while providing more accurate color matches. For instance, to determine the impact of its color choices on ADAS functionality, PPG is partnering with vehicle manufacturers on its color styles earlier in the preliminary research stage instead of after final approvals.

Automakers and paint suppliers will also take a greater role in guiding best practices for repairs as ADAS technology evolves. Body shops will need to give more consideration to the repair guidelines, technical and service bulletins, training, and tutorials provided by automakers to keep safety intact. For example, PPG will issue a technical bulletin relating to radar and the impact of certain metallic finishes for body shop professionals.

In the long-term, the automotive refinish industry will require international standards for body shops on repairs to ADAS-equipped cars to identify the acceptable loss of radar transmission following a collision. A technical standard developed by one or more organizations (i.e., carmakers, trade associations, paint and coatings suppliers or regulatory bodies) will be necessary for worldwide use as the ADAS market swells. Market research predicts a $19-billion growth in the ADAS market over the next four years, with most new cars and trucks now available with various advanced driver assistance systems.

It will also be critical for the industry to establish new solutions and future color palettes that do not impact radar and then share those standards and measurements for performance coatings with collision repair centers. Meanwhile, body shop technicians will need to continue to educate and train themselves on how to identify ADAS, as well as the art of calibration and estimation for these next-generation cars, and to be aware of how certain colors and finishes can impact the safety components that keep drivers safe.

About the Author

Nick Tullett

With 36 years of industry experience, Nick Tullett serves as a global products and segments director in PPG's automotive refinish business. At PPG, we work every day to develop and deliver the paints, coatings and materials that our customers have trusted for nearly 140 years. Through dedication and creativity, we solve our customers' biggest challenges, collaborating closely to find the right path forward. PPG's automotive refinish business is singularly focused on delivering state-of-the-art technology to meet the needs of collision repair centers. With headquarters in Pittsburgh, Pennsylvania, we operate and innovate in more than 75 countries. To learn more, visit www.ppgrefinish.com