Empowering technicians: Lessons learned from an Audi ADAS calibration

Advanced driver assistance systems (ADAS) have transformed the automotive repair landscape, introducing an era in which calibration, diagnostics, and electronic troubleshooting skills are more critical than ever. Shops nationwide are adapting quickly, but even the most experienced technicians can encounter challenges when working on these sophisticated systems. Recently at our facility, we faced an intriguing challenge involving a 2019 Audi TTS equipped with lane-change assist, providing an opportunity to highlight effective technician mentorship and the diagnostic mindset needed in modern auto repair.

Encountering the Problem

Our story begins with a seemingly straightforward task. A 2019 Audi TTS entered our shop needing its lane-change assist system calibrated after collision repairs. The lane-change assist is part of Audi's ADAS suite, which uses radar sensors to monitor adjacent lanes and alert drivers of potential hazards during lane-changing maneuvers. While routine calibrations usually proceed smoothly, this vehicle soon presented with an unexpected complication.

The job was initially assigned to one of our junior technicians who has been with our team for approximately three years. During his tenure, this technician has consistently demonstrated skill progression, confidence, and a commendable eagerness to tackle increasingly complex diagnostic tasks. His initial approach to this calibration was routine until he encountered a persistent communication error in the lane-change assist system. Installation of the system was not detected (Figure 1), which prevented his ability to perform a calibration of the system.

Diagnostic Process and Hypothesis

In our shop, we emphasize approaching diagnostics with a systematic strategy. So, our technician transitioned from calibration to diagnostics and began with foundational checks. First, he confirmed the work that was performed to the vehicle and then removed the bumper to visually confirm all modules were properly connected and secured. He then proceeded to verify the system’s fuses were intact and fully functional (Figure 2).

After completing these initial steps, the technician developed a hypothesis. Because the vehicle had recently undergone repairs in which the driver-side lane-change assist module was replaced and the passenger-side lane-change assist module was retained, he suspected a version mismatch between these two modules could be the root of the issue. This seemed logical based on his past experiences with other brands and how the problem was presenting in the Audi.

The Importance of Mentorship

Feeling confident in his assessment, the technician approached me to discuss his findings. This interaction underscores the critical role mentorship plays within the automotive repair industry, particularly when it concerns diagnostics. As an experienced technician myself, I’ve witnessed firsthand the complexities of ADAS system diagnostics. I recalled dealing with a similar Audi lane-change assist issue a few years ago, one that mirrored the symptoms my technician currently faced.

While the technician’s hypothesis was well-founded based on his experiences, his conclusions hadn't fully convinced me. Because I had experienced a similar issue, I recognized the need to thoroughly investigate to confirm the root cause of the problem. This was a prime mentorship moment: balancing encouragement of independent problem-solving skills while gently guiding the technician toward more comprehensive diagnostic methods.

I advised my technician to delve more deeply into verifying power, ground, and communication signals at the modules. My previous experience underscored how critical thorough electrical checks can be in isolating elusive diagnostic issues. Although initially hesitant, he accepted the guidance and returned to the Audi TTS with a renewed focus, now better prepared to resolve the issue with greater confidence.

Discovery and Resolution

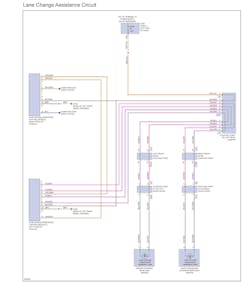

Armed with wiring diagrams (Figure 3) and a sense of clarity, the technician began to methodically identify the circuits that would need to be tested. His first important discovery was that the connector wires at the lane-change-assist module didn’t match the pin positions indicated in Audi’s technical resources. His realization signaled that something deeper than a version mismatch between modules might be at play.

Spurred by this unexpected finding, he carefully inspected the vehicle’s wiring harness and related connectors. This proved fruitful almost immediately, as he discovered that the wiring harness in the bumper had been inadvertently installed incorrectly by the collision repair technician. Specifically, the harness had been installed in reverse; the connector for the driver-side module was connected to the passenger-side module, and vice versa (Figure 4). This installation error was the root cause of the communication failure.

Once the technician corrected the harness connections, reconnecting each module properly, the lane-change assist system immediately resumed normal communication (Figure 5). With the communication error resolved, he successfully completed programming of the replacement module and calibration of the lane-change assist system, which returned the vehicle's ADAS to optimal functionality.

Key Takeaways and Conclusions

This experience with the Audi TTS ADAS calibration teaches several valuable lessons. First and foremost, junior technicians should be consistently empowered to take the initiative in complex diagnostics. Encouraging them to form hypotheses, explore possibilities, and confidently approach senior colleagues with their ideas significantly boosts professional growth and independence.

Secondly, the presence of an experienced technician as a mentor can never be understated. While independence is critical, guidance from seasoned professionals ensures junior technicians remain on the right path. Mentorship provides context, practical wisdom, and helps to prevent common or avoidable diagnostic missteps.

Finally, this event reiterated that ADAS issues often appear in unexpected ways, with resolutions not always aligning with initial assumptions. As vehicle technology evolves, technicians must maintain a flexible and thorough approach and continually be prepared for surprises. Training our teams to maintain open-mindedness and diligence when facing diagnostics, especially when ADAS is involved, is crucial to delivering quality repairs in a rapidly advancing industry.

By fostering environments where junior technicians feel supported yet challenged, we create the next generation of diagnostic experts. Technicians who will confidently navigate the complexities of modern automotive technology. The Audi TTS calibration issue turned into an opportunity for growth, mentorship, and reinforcement of diagnostic best practices.

About the Author

Paul Bostel

Paul Bostel is a seasoned leader with a rare blend of expertise in both advanced automotive technology and fire service operations. With over 20 years in the automotive industry, he is recognized as one of fewer than 2,300 ASE World Class-certified technicians — a distinction that underscores his mastery in diagnosing and repairing complex vehicle systems, with a specialized focus on ADAS. Paul currently manages Accelerated Vehicle Technology in Bloomington, Minnesota, a Quality Collision Group brand, where he applies his analytical precision and strategic mindset to elevate operational performance and repair standards. In parallel with his automotive career, Paul has proudly served the Apple Valley Fire Department for over nine years and holds the rank of captain, demonstrating his strong leadership, commitment to community service, and ability to manage high-pressure environments. His career is defined by innovation, efficiency, and a continuous drive to raise industry standards across every role he takes on.