THE INSPIRATION: As outlined in FenderBender’s July story (“Inside an F-150 Structural Repair”), after a customer tried to drive his brand-new Ford 2015 F-150 King Ranch Crew Cab through a car wash and racked up $17,000 worth of damage, Waikem Auto Body Repair Center in Massillon, Ohio, and its collision center director, Jim Shreve, completed one of the most extensive F-150 structural repairs the industry had seen since the aluminum-bodied vehicle hit the market.

Once the Waikem team started the repair-planning process, red flags began popping up left and right. One of those was the large amount of rivets in the vehicle’s body. In total, Shreve said they encountered 82 different rivets of all styles and sizes. To put it lightly, he says it’s complex, and switching between rivets and setting up the rivet gun and the pressure each time is time consuming (Shreve estimates a 20-minute setup time when switching rivets).

The repair manual has it color-coded, but Shreve says the amount of time it would take to look up each color and find the correct rivet made a quick repair impossible. Each type of rivet requires a different setting on the gun, as well, so changing in between rivets wasn’t a viable option.

SHOP: Waikem Auto Body Repair Center

LOCATION: Massillon, Ohio

MANAGER: Jim Shreve

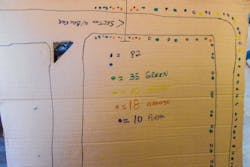

WHAT IT DOES: Shreve’s team used cardboard to make templates of the vehicle components with spots to store the rivets where they were intended to go.

“Set up would be quicker, and then they could just rifle through one type of rivet, switch settings and move on to the next type,” Shreve says. “The body man, he came up with the idea of the template and said, ‘Let’s set it out by colors of rivets so we can see how many we’ve got to do and we can do the one with the most first, then the next and then the next.’ We could do 80 at a time, switch over and do 50 of the next one, switch over. It’s more efficient than doing one and switching over, doing two and switching back.”

HOW IT’S MADE: Shreve and his body man simply took a large piece of cardboard (roughly 5 feet by 6 feet) and drew a template of the vehicle and where the rivets are located. He then color coded the rivets with their locations on the vehicle and made little cups to store all of the corresponding rivets together.

THE COST: One labor hour to create.

THE RETURN: Shreve says that the time savings was significant for the repair moving forward and that he anticipates it will significantly speed up future F-150 repairs. He says that prior to constructing the template, his team took a week figuring out where the rivets went on the vehicle and how to more efficiently organize them. After creating the template, he says the team was able to work on the repair without stopping.

“The workshop wasn’t real explicit or in depth on how to do it,” he says. “It just said drill these rivets out and do this and that. Not a lot of anything that you had to switch mandrels and the pressures each time. Then we figured out that each rivet, because there are different sizes, requires a different pressure and a different end.”