Role Reversal

There’s the old adage that shop leaders should strive to work on their business rather than in it. Meaning, shop operators should focus their energies on high-level business strategies instead of fixing cars.

That’s true, but remember that improving the shop floor is an example of working on your business. You can’t hole up in your office developing marketing strategies and completely forget about shop operations.

Gary Boesel, owner of Jordan Road CARSTAR Auto Body Repair Experts and Alpine CARSTAR Auto Body Repair Experts in Colorado, says it’s easy for owners to get stuck at their desk working on business initiatives. But losing sight of the happenings inside the shop reduces your connection with technicians, as well as your ability to coach, guide and learn from them.

“Smart shop leaders always have their finger on the pulse of their technicians and processes,” Boesel says. “You need to have a handle of what’s going on.”

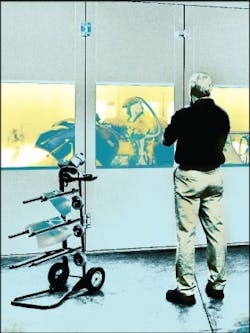

Informally shadowing your technicians is the perfect solution. Spending just a few minutes with each of your technicians every week—watching them work, assessing their techniques, and observing their materials and equipment—is a leadership tactic that can reveal several ways to improve your shop and maintain relationships with staff. It helps shop leaders understand technician challenges, tap employees for new ideas and monitor employee skill sets.

Ultimately, you can coach technicians better, set realistic expectations and make better business decisions.

FenderBender talked to Boesel and other shop operators who regularly shadow their technicians. They discuss why it’s beneficial for their businesses, and how it’s boosted their abilities as leaders.

Gary Boesel,

owner of Jordan Road CARSTAR and Alpine CARSTAR in Colorado

Why he shadows: Boesel says his job as the shop leader is to acquire as much information as he can from a variety of sources and convey new knowledge to his staff. Technicians are confined to their everyday jobs, and don’t have many opportunities to find new ideas for improvement on their own, he says.

But Boesel makes a point of traveling the country, visiting other shops and attending trade shows to learn about possible upgrades to his shop.

—Gary Boesel, owner, Jordan Road CARSTAR

He spends roughly 20 minutes a day shadowing his technicians in every department. He identifies their daily challenges, and what needs they have to improve.

He takes note of their processes, techniques, tools and equipment to see how he can implement new things he’s learned elsewhere.

The goal, Boesel says, is to become more efficient and resolve technicians’ daily obstacles. “I’m not there to critique their work or processes,” he says. “I shadow just to bring value and help them get better.”

Business benefits: Boesel says the shadowing process has kept him in tune with the services that his company provides.

New vehicle technologies and designs are constantly popping up, and keeping an eye on the shop floor keeps him up to date.

“Although I can’t necessarily do a technician’s job, it’s important to have some concept of the things they’re working on,” Boesel says.

He deliberately shadows technicians every time they work on something he’s never seen, such as a new-model vehicle with an exotic metal.

He assesses how the repairs are made, and any challenges technicians run into in the process.

That helps Boesel stay mindful of new tools, equipment, information or training to look for. “As the leader, I always need to be able to relate with what technicians are working on,” Boesel says. “That’s what helps me make good business decisions.”

Leadership lesson: Boesel says shadowing technicians has given him a chance to spend more one-on-one time with them than he otherwise would do.

Ensuring interactions on a consistent basis has helped him develop stronger relationships.

“Employees know you have a vested interest in every level of the shop when you engage with them,” Boesel says. “They know I care about their success, which improves morale and culture.”

Boesel’s top tip: Boesel says it’s important for shop leaders to spend time shadowing every technician; rotate to someone new each time. But getting around to everyone can be tough—and time consuming—if you’ve got more than 10 technicians.

Boesel has 28 technicians and can’t always get around to everyone. So he delegates some of the responsibilities to his management team.

“You can build the importance of shadowing into your store culture. Put those responsibilities out there, and your management will follow suit,” Boesel says. “Start with the vision, and cascade those values down to management.”

Matthew Rex,

manager of T Bar S Body Shop in Evanston, Wyo.

Why he shadows: With very little experience in the paint department, Rex is focused on educating himself. He wants to absorb as much information as possible about paint operations and necessary skill sets.

Rex recently hired a painter who had several years of experience and great references to head up the paint department. After a while on the job, body technicians started noticing quality issues in paint jobs that were slipping under Rex’s nose. The painter had no idea how to prep a car: He wasn’t cleaning surfaces, didn’t know how to mask, and sidestepped certain processes altogether.

With no painting experience, Rex said he never would have noticed the problems, and would not have known how to fix it, if his body technicians hadn’t spoken up.

That was a wake-up call for Rex, he says. “I realized that I need to learn everything about the business so that I don’t need to rely on one of my employees to point out problems,” he says. “I need to know everything about working in the shop, not just the office.”

Rex now spends two hours in the paint shop about three days a week. He says his goal is to acquire information about processes, procedures, techniques and workflow so that he can lend a hand when necessary, know what skills to look for in new hires, and develop detailed standard operating procedures (SOPs) for the painting process.

Business benefits: Rex says the shadowing effort has allowed him and his painters to learn from one another—to the benefit of the entire paint department. He reads information that the painters don’t always see, and they have experience with paint brands and equipment to offer suggestions for improvement.

For example, Rex passed a tip on to his painter about the quality benefits of using lifting tape to mask. His painter was able to show Rex the quality problems with his paint line, and the potential benefits of switching to a new brand.

Rex says the combination of the changes dramatically improved output and cycle time by eliminating problems with application, color match, clear coat and blemishes.

Rex says those changes could have been made long ago. But it wasn’t until he opened dialogue with the painter through shadowing that the improvements came to light.

Leadership lesson: Rex says his technicians are now more willing to listen to his suggestions and accept changes he implements. He says shadowing technicians is one way to show that you understand and can relate to the challenges they deal with. So instead of resisting change, technicians understand that new initiatives are meant to resolve some of their specific problems—not to make things more difficult.

“That has developed management and technicians into a cohesive team, which has improved camaraderie and morale in the shop,” Rex says.

Rex’s top tip: Rex says technician shadowing also provides a perfect opportunity to get to know your staff on a more personal level. He suggests spending a few minutes discussing nonwork topics, such as families or home life.

“Those things are important for small business owners to know about their employees,” Rex says. “It’s caused technicians to feel more comfortable approaching me to talk.”

Greg Lobsiger,

owner of Loren’s Body Shop in Bluffton, Ind.

Why he shadows: Lobsiger says you can’t always assume that technicians know how to do their job the best way. He uses the shadowing process to learn what his best technicians are doing right so he can better coach and guide those who need improvement. He spends 15 minutes with each technician everyday to ensure they’re are all on the same page, and always following best practices.

Business benefits: Lobsiger says technician shadowing has allowed him to maintain steady workflow in the shop.

He is fully aware of when a technician needs help, which has fostered better teamwork and proactive resolutions to problems.

For example, Lobsiger had one technician who worked as fast as he could. He moved from job to job in fast-forward. He had another technician who moved at half the speed, but produced 40 percent more work every week. So Lobsiger spent time with each of them to identify why the slower worker was more effective.

It turns out the speedy technician was extremely unorganized. He misplaced parts, tools and materials, and spent the majority of his time searching for lost items.

The other technician, however, knew where every wrench and bolt was placed at all times. Lobsiger was able to take note of the higher producer’s processes, and educate the other technicians on replicating his habits.

“You can only get that insight by spending time with your technicians to find out what they’re doing right and wrong,” he says, noting that every technician works a bit differently. “That’s how you identify process and habits that might suit them better.”

Leadership lesson: Lobsiger says some shop owners constantly push technicians for improved efficiency, but don’t take time to understand issues that cause delays.

Shadowing helped him understand technicians’ daily challenges. He can now relate to and empathize with technicians, and avoid setting unachievable expectations.

He says that helps with things such as scheduling repairs, and assigning jobs.

Lobsiger’s top tip: Take advantage of exclusive conversations with technicians to offer positive recognition.

Show appreciation for their work efforts, and give them a pat on the back to show you care. “That keeps you connected,” he says.