Lightweight material repair considerations

As the automotive industry moves toward lighter and more efficient vehicles, the importance of advanced training for collision repair technicians has never been greater. Both performance and regulatory factors influence the drive for lighter vehicles. For internal combustion engine (ICE) and hybrid vehicles, a lighter weight is essential for meeting increasingly stringent fuel efficiency standards, such as the Corporate Average Fuel Economy (CAFE) standards. For electric vehicles (EVs), lighter weight directly impacts the range of the vehicle, offering a competitive advantage for manufacturers striving to extend battery life and improve performance. Both of these trends are pushing the demand for lightweight materials in vehicle construction, which presents unique challenges for repair technicians.

The Role of Training in Lightweight Material Repair

Technicians and shop owners must recognize the importance of embracing a comprehensive approach to training, which includes both OEM-specific education and broad-spectrum foundational programs like I-CAR training. It is highly recommended that technicians, along with engaged shop owners and managers, fully embrace the OEM training available, especially for specialty and high-end vehicles. OEM training provides invaluable insights into vehicle manufacturer service information, service bulletins, and collision repair publications, which are essential for ensuring the accuracy and integrity of repairs.

While I-CAR training offers a strong base of general knowledge — covering topics like attachment methods, structural repair and advanced materials — this foundational training prepares technicians for more specialized OEM programs. I-CAR’s broad training spectrum helps technicians become familiar with key repair concepts and techniques that they will later encounter during more detailed OEM training. By combining both OEM-specific education and versatile training programs, repair professionals can ensure they are fully equipped to meet the demands of modern vehicle repairs, particularly when dealing with lightweight materials and advanced technologies.

Specialized Techniques for Lightweight Material Repair

The repair of lightweight materials requires technicians to stay in line with OEM-specific procedures, which differ significantly based on the material in question. On the steel side, advancements like ultra-high-strength steel enable thinner, stronger components, but they also introduce the risk of losing structural integrity if improperly repaired. Technicians must be trained to recognize when sectioning or full part replacement is necessary and follow the manufacturer’s guidelines for attachment methods, whether it’s welding or cold joining methods like rivet bonding.

Aluminum-intensive vehicles, such as the Ford F-150, have further driven the adoption of rivet bonding techniques over traditional welding. While welding is still sometimes required, manufacturers increasingly prefer cold joining methods to avoid weakening the material. I-CAR’s specialized courses help technicians navigate these changes, ensuring they adhere to correct attachment methods to preserve the integrity of the vehicle.

Navigating Repair Limitations and Part Replacement

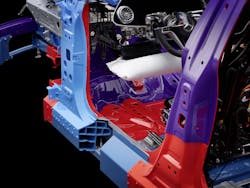

As lightweight materials like aluminum and high-strength steel become more common, repair processes must adapt. In some cases, repairability may be limited, and part replacement becomes the only option. The complexity of materials, such as layering within a part or integrating different materials (steel, aluminum, and carbon fiber), can make repairs more challenging. I-CAR training prepares technicians for these scenarios by teaching them how to evaluate the repairability of a part, whether sectioning is allowed, and when full part replacement is necessary. -photo showing the layering

OEM procedures play a critical role in maintaining safety and performance standards. For example, using the wrong welding technique on ultra-high-strength steel can weaken the part, compromising the vehicle’s safety. As one expert noted, “It’s not about your ability as a technician — it’s about following the OEM requirements to ensure the vehicle performs as designed.” This highlights the need for ongoing, specialized training to ensure technicians do not inadvertently compromise the vehicle's structural integrity during repairs.

The Importance of Hands-On Training

Repairing lightweight materials requires practical, hands-on training to refine skills. Technicians should practice on scrap materials, particularly in welding and bonding exercises, to ensure they can execute repairs accurately. I-CAR's hands-on approach allows technicians to simulate real-world scenarios, such as performing repairs on aluminum or high-strength steel, before working on customer vehicles. This practice builds confidence and ensures that repairs are performed with precision.

Continuous Learning and Adaptation to Emerging Technologies

As vehicle technology evolves, so must the skill sets of collision repair technicians. Lightweight materials are not only essential for meeting fuel efficiency and range goals but are also vital for the continued development of electric and autonomous vehicles. Technicians must stay updated on new material types, advanced tools, and the latest repair techniques to ensure they can repair modern vehicles safely and effectively. Whether through I-CAR courses, OEM certifications, or manufacturer-specific training, ongoing education is critical for technicians to stay ahead of industry trends and deliver high-quality repairs.

The push for lighter vehicles, driven by fuel efficiency standards for ICE vehicles and range requirements for EVs, is reshaping the collision repair landscape. Repairing these vehicles requires technicians to possess specialized knowledge and skills, particularly when working with lightweight materials like aluminum, carbon fiber, and high-strength steel. I-CAR training, with its focus on OEM-specific procedures and hands-on experience, ensures that technicians are prepared to meet these challenges head-on. By prioritizing continuous learning and following manufacturer guidelines, the collision repair industry can maintain high standards of safety and repair quality, ensuring that every vehicle remains roadworthy and performs as designed.

I-CAR's OEM Linking Pin

As part of its Repairability Technical Support (RTS) OEM linking pin activity, I-CAR helps connect the collision repair industry to the vehicle makers. One example is this one, titled Ford Aluminum Vehicle Running Board Mounting Location Repairability, found here: https://rts.i-car.com/crn-1995.html:

"A common question when it comes to the 2015-present Ford F-150 is the repairability of the running board mounting location. Specifically, when the stud is torn out of the inner rocker panel. We reached out to Ford for clarification.

Per our contact at Ford, the following procedure applies to these vehicles:

2015-present Ford F-150

2018-present Ford Super Duty

2018-present Ford Expedition

2018-present Lincoln Navigator

Per our contact at Ford: "They can do weld repair to the stud areas. The inner rocker panel can be sectioned where required. The repair facility can order the inner rocker and cut out a plate around the stud and weld it in following the sectioning guidelines outlined in the repair manual. It would be very invasive to replace the inner rocker panel unless there was additional damage to the inner rocker panel beyond the torn-out stud."

This means there are several repair options to consider when assessing the damage and the extent of the repair to be completed:

Repair/straighten the stud mounting area and weld any cracks or tears in the immediate stud location.

Following Ford’s sectioning guidelines, cut a portion from the new inner rocker panel service part and install accordingly.

Replace the inner rocker panel at factory seams. This requires the outer uniside and the rocker panel reinforcement to be replaced. This should be considered if there is additional unrepairable damage beyond the torn-out stud(s)."

About the Author

Scott Kaboos

Principal, OEM Technical Relations Lead and Subject Matter Expert

Scott spent the first 20 years of his career in the collision industry as a structural repair technician. In that time, he worked for independent, dealership, and MSO shops. In 2014, he began a new chapter as a collision instructor at the High school and college level including becoming the Program Coordinator for the prestigious Fayetteville Technical College, Collision U program where he was recruited by American Honda to develop their collision technical training program. Scott is a 6 category I-CAR platinum individual, 3x Recertified ASE Master Collision technician and has earned AMCE and AMAM designations with AMI. He has also been a part-time welding instructor for I-CAR for the past seven years. In his spare time, Scott enjoys building street rods and restoring antique cars.

Jeff Poole

Manager, Subject Matter Expert

Jeff first ventured into a commercial shop in the late ’80s and not long after that was enrolled in some I-CAR classes. Many days in the collision shop repairing vehicles and presenting I-CAR courses in the evenings eventually led to national I-CAR recognition, when Jeff was awarded “Instructor of the Year" for 2005.

From repairing vehicles as a technician to helping with the development of training materials for the collision repair industry here in the U.S. and viewed in other countries, with over 35 years in the industry Jeff is a sought-after subject matter expert when it comes to identifying the important aspects of a scenario and how it applies to collision (or other loss type) and vehicle repairs for application in educational resources.